Electric Vehicle Charging Connector Procurement Intelligence

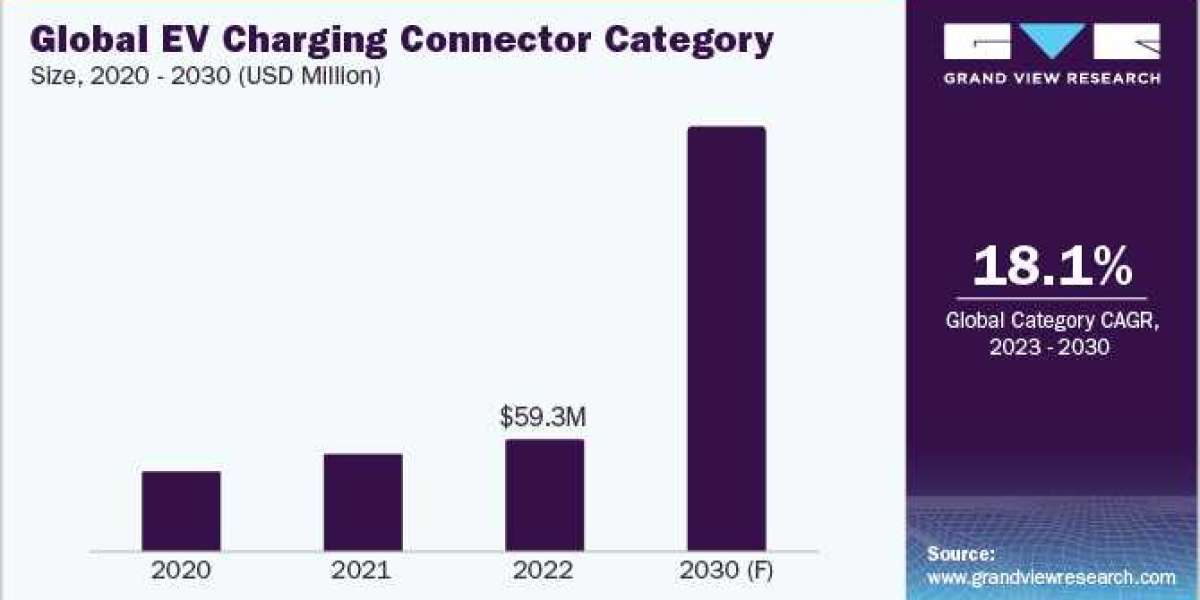

The electric vehicle charging connector category is expected to grow at a CAGR of 18.09% from 2023 to 2030. The increasing demand for charging stations reflects a shift towards cleaner and sustainable transportation solutions. IEA 2023 global estimates show that in 2022, more than 600,000 public slow charging stations were installed in China. Europe ranked second with 460,000 chargers in 2022. For Europe, this was a 50% increase in 2022 from 2021. Netherlands, France, and Germany had the highest chargers installations within Europe. In the U.S., the stock of slow chargers rose by 9% in 2022. In the case of fast chargers, China accounted for 760,000 units. The European governments are aggressively pushing for the development of public EV charging stations to comply with the Alternative Fuels Infrastructure Regulation (AFIR). The presence of public charging points is becoming more important to facilitate the adoption of EVs on a larger scale, which in turn, boosting the category’s growth.

The main obstacle to the swift adoption of electric trucks for regional and long-haul operations is the availability of "mid-shift" quick charging. At present, there exist multiple charging standards in use, and technical specifications for ultra-fast charging are currently under development. The charging connector can be divided into Type 1 (or J Plug or SAE J1772), Type 2, CCS Type 1, CCS Type 2, CHAdeMO, GB/T and Tesla connectors. The North American Charging Standard (NACS), also known as the Tesla charging standard, is currently being standardized as SAE J3400. This is one of the most popular trends in the industry. Even though EV sales surpassed 1 million in the U.S. in 2023, the nation still stands behind China and Germany. This can be primarily attributed to the limited availability of charging infrastructure in the country. Hence, as part of increasing sales strategy, Tesla plugs are to be used for all EVs in the U.S. in the near future.

Order your copy of the Electric Vehicle Charging Connector category procurement intelligence report 2023-2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

The global EV charging connector category is fragmented. The charging stations, overall, have witnessed significant growth in China. The electric vehicle charging value chain consists of a range of stakeholders. At the upstream level, manufacturers specialize in providing critical equipment for station construction such as shells, cables, and connectors/plugs. The midstream level mainly comprises operation and construction companies that manage the charging stations. The downstream segment encompasses a cohort of companies that specialize in providing reservation and location services, payment functionalities, and operational management platforms. These services are designed to facilitate seamless integration across the value chain, thus improving the overall experience.

The key costs involved in the production of EV charging connectors are raw materials/wires/cables, energy or electricity, machining/tooling/ laser equipment, labor, mounting accessories, housing and packaging, and facilities. Copper is a highly versatile and sought-after raw material due to its exceptional electrical conductivity and corrosion-resistant properties. It is extensively utilized in the wiring and electrical components of charging stations, owing to its reliability and efficiency.

In order to commercialize chargers rated at 1 MW, a significant investment will be necessary due to the high costs associated with grid upgrades and installation. Ideally, charging stations should be located near transmission lines and substations in highway depots to minimize costs and increase charger utilization. China, Japan, South Korea, the U.S., and Germany are the most preferred countries for companies looking to source EV charging connectors. Most automotive companies or OEMs or EV makers prefer adopting a hybrid outsourcing engagement model with cable manufacturers.

While selecting EV charging connector vendors, it is extremely important to check the charge speed levels, typical charge time, range per hour, the network offered, and the presence of any one-time installation or recurring costs. The cable or connector manufacturing expertise and knowledge are also crucial elements to factor in during purchase decisions. Type 1, 2, or 3 connectors should strictly meet the technical guidelines to ensure safety and reliability.

Electric Vehicle Charging Connector Sourcing Intelligence Highlights

- The category is fragmented. However, the top eight to ten players such as Tesla, ABB, Bosch, Siemens, Schneider, Yazaki, and Sumitomo hold dominant market positions with better negotiation power.

- Regionally in China, as per 2022 estimates, TGOOD dominated with 40% of the total BEV charging station sector/market share. In 2022, the top five companies in the charging operations sector were TGOOD, Star Charge, YKC, State Grid, and Xiaojuchongdian in China.

- The cost to manufacture a wire or cable can in turn depend on several factors such as the type of metals used-steel or copper, type of wiring, size, and thickness. Copper is a major component used in EV motors, batteries, wiring, and charging stations. In September 2023, global copper prices reached USD 8,535 per MT.

- The most preferred countries for procuring this category are China, Japan, South Korea, the U.S. and Germany. Most of the automotive companies or OEMs or EV makers prefer adopting a hybrid outsourcing engagement model with cable manufacturers.

List of Key Suppliers

- ABB Ltd.

- Bosch Automotive Service Solutions LLC.

- Tesla, Inc.

- Siemens AG

- YAZAKI Corporation

- Sumitomo Electric Industries, Ltd

- Huber + Suhner AG

- ITT Cannon Inc.

- Amphenol Corporation

- Fujikura Global

- Aptiv PLC

- Hirose Electric Co., Ltd

Browse through Grand View Research’s collection of procurement intelligence studies:

- Rental Cars Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement Operating Model, Competitive Landscape)

- Catering Service Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement Operating Model, Competitive Landscape)

Electric Vehicle Charging Connector Procurement Intelligence Report Scope

- Electric VehicleCharging Connector Category Growth Rate: CAGR of 18.09% from 2023 to 2030

- Pricing Growth Outlook: 5% - 18% (Annually)

- Pricing Models: Cost-plus and time-based, energy-based, fixed rate, and hybrid pricing models

- Supplier Selection Scope: Cost and pricing, past engagements, productivity, geographical presence

- Supplier Selection Criteria: By socket type, charging power and time, electric consumption, operational and functional capabilities, quality measures, standards followed, certifications, regulations, and others

- Report Coverage : Revenue forecast, supplier ranking, supplier positioning matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

- Market Intelligence involving – market size and forecast, growth factors, and driving trends

- Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

- Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

- Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions