Machine Vision Industry Overview

The global machine vision market size was valued at USD 18,475.6 million in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 12.7% from 2024 to 2030.

The increasing demand for quality inspection and automation in different industrial verticals is likely to drive the market. Additionally, the need for vision-guided robotic systems across the automotive, food and beverage, pharmaceutical and chemical, and packaging segments is expected to fuel the market growth. The surge in demand for application-oriented machine vision systems is also boosting the adoption of the technology over the forecast period. MV systems involve the ability of a computer to observe, inspect, and scrutinize the work performance by employing one or more video cameras, digital signal processing, and analog-to-digital conversion. The captured data is then transferred to the computer to analyze and provide the desired output. Resolution and sensitivity are two important aspects of any MV system. Resolution is responsible for differentiating between objects, whereas sensitivity is the machine’s ability to detect objects or weak impulses despite dim lights or invisible wavelengths.

Gather more insights about the market drivers, restrains and growth of the Machine Vision Market

These systems particularly assist in supervising work environments. It offers features such as process control, robotic guidance, and automatic inspection in industrial applications. Industrial production and manufacturing activities are becoming increasingly complicated day by day, creating difficulties and increasing unreliability for the human eye to keenly detect, observe, and examine production activities.

The adoption of machine vision technology in industrial operations has surged, notably supplanting manual inspection and measurements due to the escalating demand for efficient and reliable inspection processes. Machine vision systems, incorporating advanced machine vision cameras and sophisticated image processing capabilities, play a pivotal role in automating measurements and inspections. This integration enhances precision, speed, and accuracy, thereby meeting the imperative for heightened quality control and operational efficiency in diverse industrial applications.

The intensifying need for superior inspection and increasing automation are the key influencing factors paving the way for the notable adoption of machine vision technology. Furthermore, the need for increased quality control by consumers and manufacturers, coupled with government regulations to abide by the prescribed specifications, is expected to catapult the adoption of machine vision technology.

The technology is gaining considerable traction across food and packaging, automotive, pharmaceutical, and other industrial verticals owing to abilities such as improved detection of objects, enhanced analysis, monitoring tolerance, and accurate component measuring.

All these factors are expected to boost the market growth over the forecast period. However, the lack of efficient system operators due to inadequate training is a restraining factor that is likely to obstruct the smooth growth of the market.

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

- The global geospatial solutions market size was estimated at USD 385.49 billion in 2023 and is projected to grow at a CAGR of 14.6% from 2024 to 2030.

- The global aviation software market size was estimated at USD 10.68 billion in 2023 and is expected to grow at a CAGR of 7.2% from 2024 to 2030.

Machine Vision Market Segmentation

Grand View Research has segmented the global machine vision market based on offering, product, application, end-use industry, and region:

Machine Vision Offering Outlook (Revenue, USD Million, 2017 - 2030)

- Hardware

- Camera

- Frame Grabber

- Optics/Lenses

- LED Lighting

- Processor

- Software

- Barcode Reading

- Standard Algorithm

- Deep Learning Software

- Services

- Integration

- Solution Management

Machine Vision Product Outlook (Revenue, USD Million, 2017 - 2030)

- PC Based

- Smart Camera Based

Machine Vision Application Outlook (Revenue, USD Million, 2017 - 2030)

- Quality Assurance and Inspection

- Positioning and Guidance

- Measurement

- Identification

Machine Vision End-use Industry Outlook (Revenue, USD Million, 2017 - 2030)

- Automotive

- Pharmaceuticals Chemicals

- Electronics Semiconductor

- Pulp Paper

- Printing Labelling

- Food Beverage (Packaging and Bottling)

- Glass Metal

- Postal Logistics

- Others (Agriculture, Security Surveillance, Rubber, Plastics, Solar Paneling, Machinery, and Others)

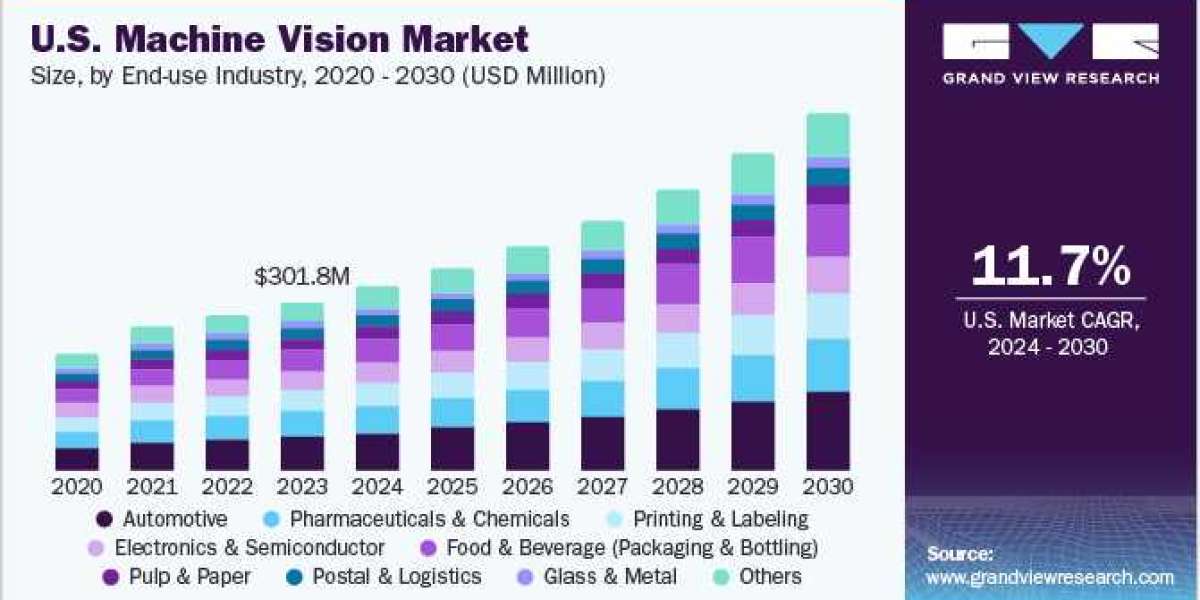

Machine Vision Regional Outlook (Revenue, USD Million, 2017 - 2030)

- North America

- U.S.

- Canada

- Mexico

- Europe

- U.K.

- Germany

- France

- Italy

- Asia Pacific

- China

- Japan

- Australia

- Singapore

- India

- South Korea

- South America

- Brazil

- Middle East Africa

- Israel

Key Companies profiled:

- Allied Vision Technologies GmbH

- Basler AG

- Cognex Corporation

- Keyence Corporation

- LMI Technologies, Inc.

- Microscan Systems, Inc.

- National Instruments Corporation

- OMRON Corporation

- Sick AG

- Tordivel AS

Key Machine Vision Market Company Insights

Some of the key players operating in the market include, Keyence Corporation and Sick AG among others.

- Keyence Corporation develops and manufactures industrial automation and inspection equipment across the globe. The company’s products include code readers, static eliminators, laser markers, sensors, machine vision, microscopes, and measuring systems. Additionally, the company offers pressure, temperature, analog, and flow sensor controllers for monitoring equipment processes.

- Sick AG is engaged in the production of sensors and sensor solutions for industrial applications. It operates through process automation, logistics automation, and factory automation segments. It provides a broad range of product portfolio including encoders, photoelectric sensors, proximity sensors, opto-electronic protective devices, magnetic cylinder sensors, and safety switches among others.

Recent Developments

- In June 2023, Allied Vision Technologies Gmbh, exhibited a substantial range of technologies and products at ‘Automatica’ in Munich. These included the ‘Alvium G1’ and ‘Alvium G5’ small GigE Vision and 5GigE Vision cameras; the launch of the company’s ‘AI-Blox’ platform together with its upcoming GMSL-2 Alvium GM2 camera; the Nerian 3D depth camera ‘Ruby’; and a look at the company’s Goldeye XSWIR camera.

- In June 2023, Omron Automation Americas launched the F440 Smart Camera for providing flexibility to machine vision operations. It includes a high resolution sensor, customizable lighting and optics, and a simplified vision system configuration via the ‘AutoVISION’ software. The camera is useful in applications including cap inspection, box count, fill level inspection, measurement, and label barcode OCR, among others.

- In June 2023, SICK Ag announced its new multiScan100 family with the launch of the ‘multiScan136’, which uses time of flight (TOF) measurement to create a 3D perception of its surroundings. The multiScan136 provides 3D measurement data for accurate self-localization of vehicles, while simultaneously mapping the environment. It has been indicated for use in mobile robotics in logistics and manufacturing, and indoor outdoor measurements.

Order a free sample PDF of the Machine Vision Market Intelligence Study, published by Grand View Research.